Features

Base Features

Touch-Screen Operation

The UHarvest Pro system works on every ISOBUS Virtual Terminal display. The easy-to-use platform permits easy setup and operation directly from a monitor that you already have in the tractor cab. No need for additional monitors, cabling, batteries or mounts!

Harvest Data Structure

Track each load using the grower (max 50), farm (max 500) and field (max 1,000) structure as well as truck, destination and crop variety for complete harvest data reporting. Easily log bushels by truck, destination and crop variety including the ability to add custom crop types. Plus, with UHarvest Pro, you can setup bin and truck capacities to help you manage your harvest operation.

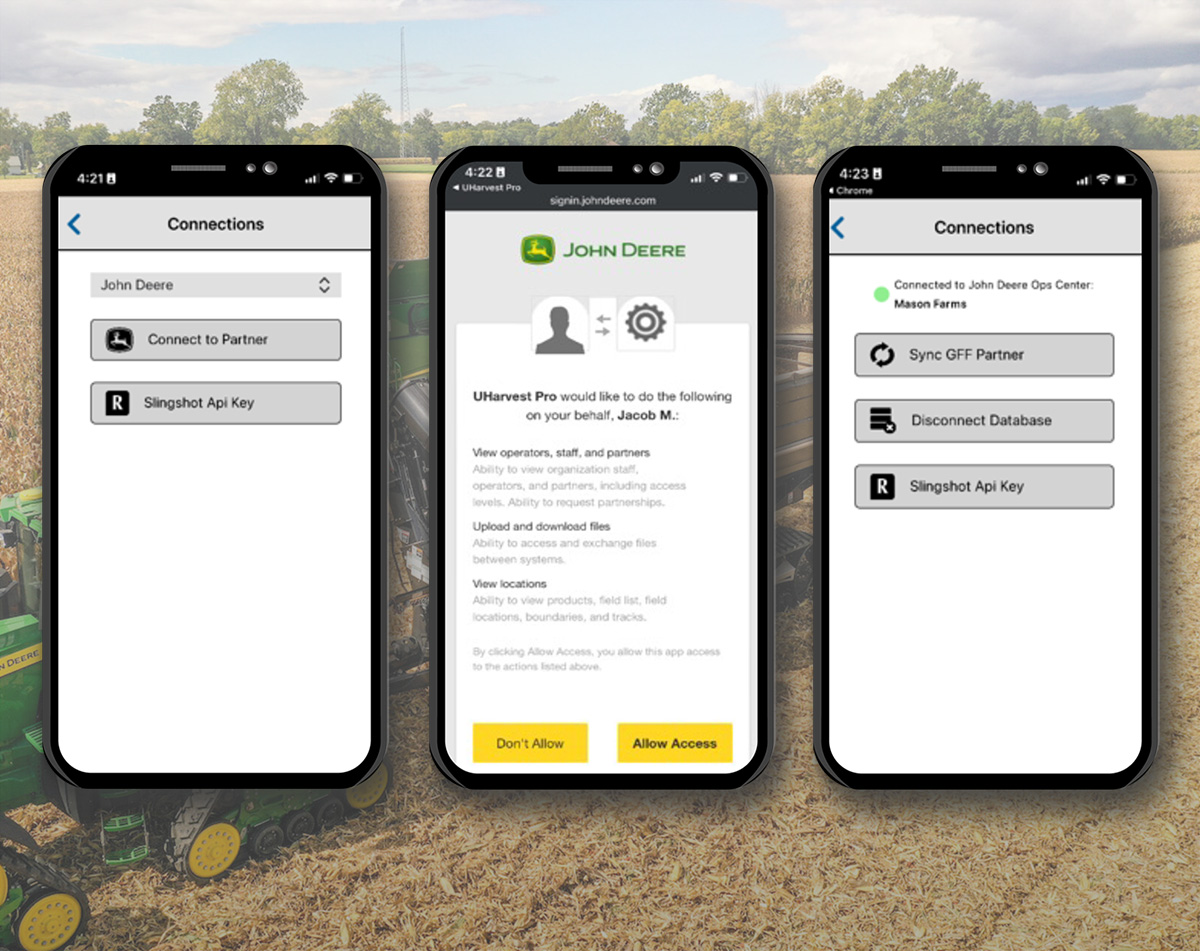

Data Connections

Connections allows you to easily import your grower, farm and field information in the John Deere Operations Center™ into your UHarvest Pro grain cart scale system by using the new mobile app. The process of importing the grower, farm and field information that is already setup in your John Deere Operations Center is quick and easy! Simply connect the UHarvest Pro mobile app to your John Deere Operations Center account and you’re all set. The manual sync button allows the operator to automatically import changes from the Operations Center database into the UHarvest Pro system. This saves you time and promotes accuracy and continuity between the UHarvest Pro system and your John Deere Operations Center.

Accu-Save Data Recording

The UHarvest Pro system automatically records each load (max 10,000) using the proximity sensor mounted on the driveshaft of the grain cart for the most accurate and complete harvest record keeping possible. The operator can simply pull up to the truck and start unloading without worrying about starting and stopping the scale.

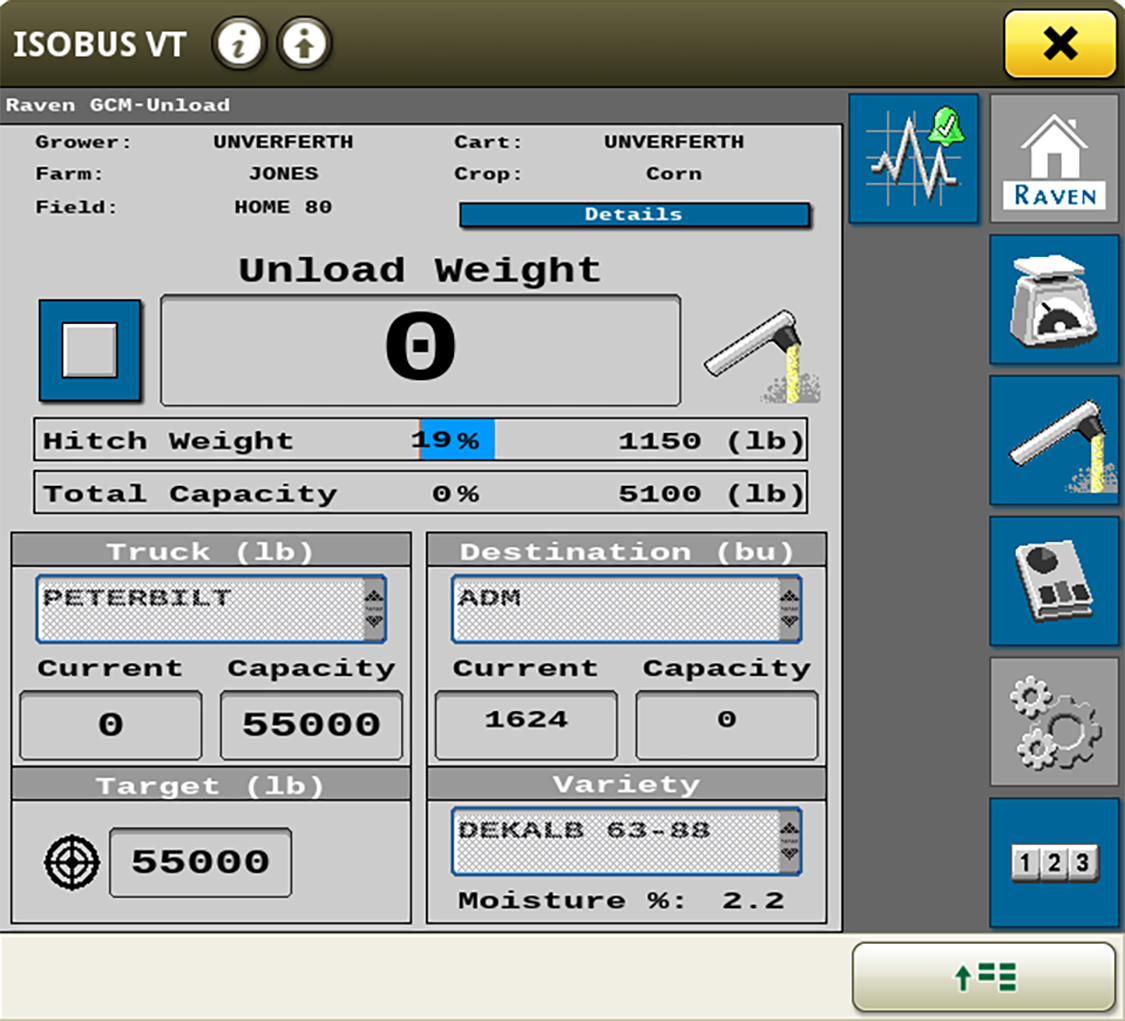

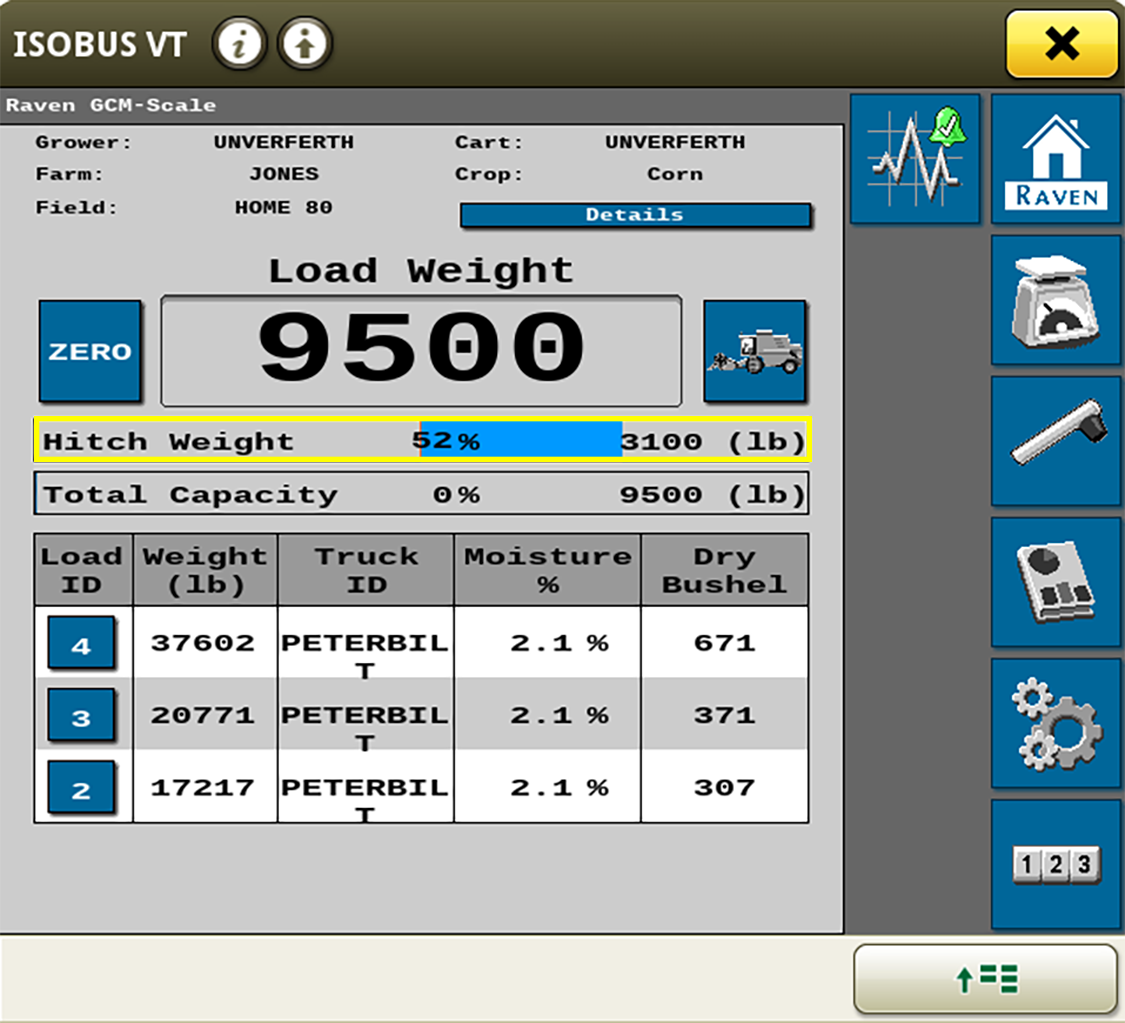

Hitch Weight Management

Maintain optimum tractor and cart control by keeping the grain load evenly distributed. This feature not only monitors grain and total cart weight, it also shows real-time hitch weight and a color gauge to avoid overloading the hitch when catching grain from the the combine.

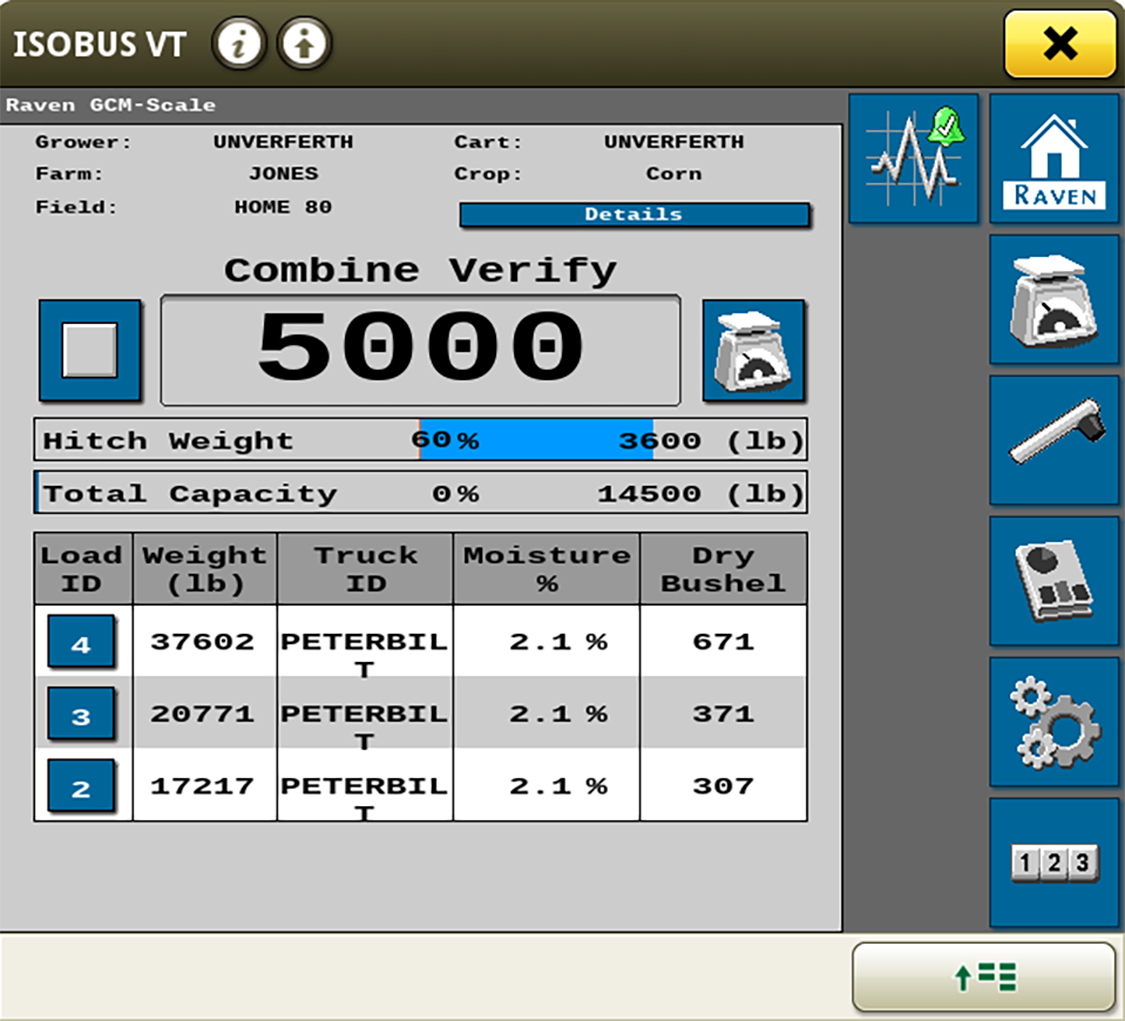

Combine Yield Monitor Verifcation

Use the Scale Report screen to easily calibrate the combine yield monitor with one touch. This calibration event is saved in the UHarvest Pro system once the verification process is completed. Easily reference a history of combine calibrations for greater accuracy and control.

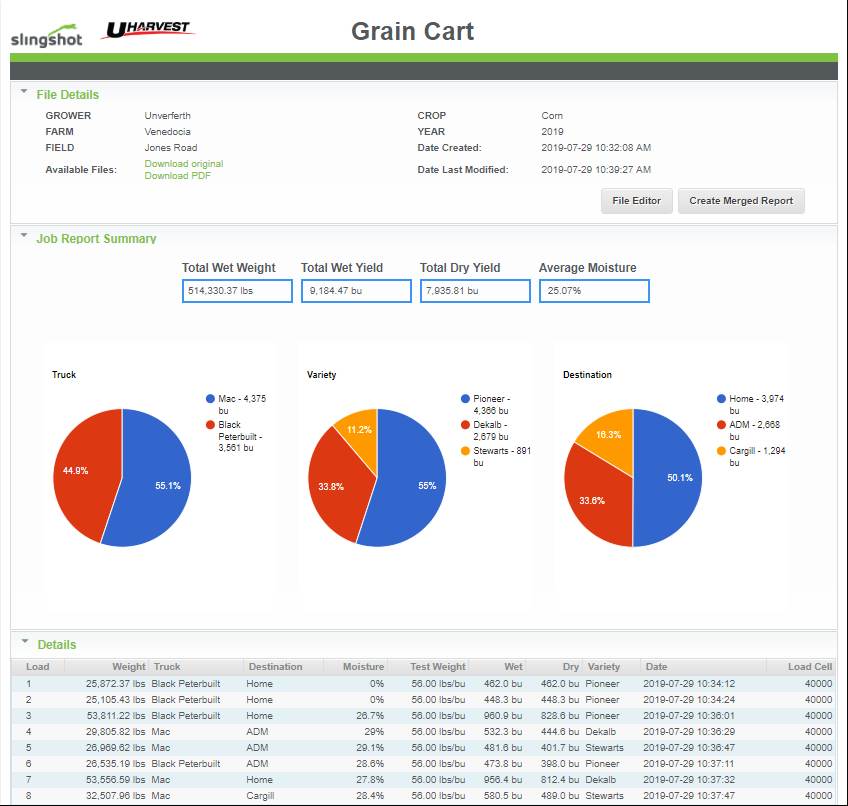

Slingshot Cloud Reporting

Slingshot is a secure, first-of-its-kind, web-based system that lets you send, store and share your harvest data. Plus, it's included free with your purchase of the UHarvest Pro system! Using the free UHarvest Pro app, you can easily send files from the field on a mobile device with cellular connection to your Slingshot account.

Data Transfer

The free UHarvest Pro mobile app allows you to send your harvest data to the Slingshot cloud reporting system directly from the field. Once you have connected your mobile device to the Bluetooth connection provided by the grain cart module (GCM), launch the app and you're ready to go. Upload once a day or once a season. It's easy to use and completely up to you! Available on IOS and Android devices.

Optional Features

Accu-Load Technology

The optional Accu-Load technology provides quick and easy loading of trucks by closing the grain cart's flow gate when the desired weight is unloaded. After you've installed the HCV (hydraulic control valve) on the cart, all you need to do it push the [Auto] button for precise weight unloading. Each truck weight is matched to the truck name for easier operation. The operator can then focus on topping off each truck, and proper grain placement.

Moisture Sense Technology

Want to easily send a report to your crop insurance agent that includes the actual dry bushel count? Consider it done with the optional Moisture Sense system. It measures grain moisture as it leaves the cart and averages the content of each load, then converts all grain unloaded to standard dry bushels for the ultimate in harvest record keeping.